Polyurethane Wheels

Polyurethane is a castable polymer class that is valued for its excellent wear resistance, easiness to use/mold, resistance to harsh environments (such as heat/acids/oil), high noise reduction properties, high abrasion resistance, and high-quality surface finish. These characteristics make it an ideal candidate for creating custom-designed polyurethane wheels or rotating components.

How are Polyurethane Wheels Used?

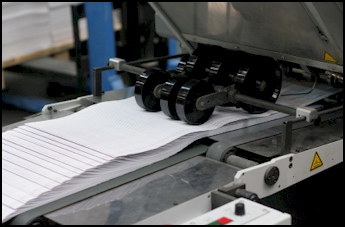

Polyurethane wheels offer the elasticity of rubber wheels coupled with the strength and durability of metal wheels, making them an ideal choice for a wide range of applications, such as:

| Conveyor Belt Systems | Chain Drive Systems | Assembly Line Systems | Drive Wheels | Crown Wheels | Guide Wheels |

| Skateboard Wheels | Caster Wheels | Chair Casters | Skate Wheels | Pulley Wheels | Dolly Wheels |

| Swivel Wheels | Railroad Wheels | Rail Wheels | Wagon Wheels | Wheelchair Wheels | Track Wheels |

Benefits of Polyurethane Wheels

Polyurethane wheels offer a high degree of customization. Each wheel can be customized by hardness, color, durability, flexibility, and tear strength. This means that polyurethane wheels offer benefits unmatched by metal, plastic, and rubber wheels. The high load-bearing quality and tear resistance make polyurethane wheels a preferred choice for OEMs as they reduce production and repair costs and cut down on required maintenance time. MPC has an expert team of designers and manufacturing engineers who can create custom polyurethane wheels that work for any purpose or application in short and long production runs.

Some of the many benefits that polyurethane wheels offer include:

| Exceptionally long service life compared to plastic, rubber, and steel wheels, ensuring lasting durability and reliability | Remarkable noise reduction capabilities, creating a quieter operational environment for enhanced comfort and productivity |

| Enhanced grip and superior traction on various surfaces such as paper, glass, & wood, optimizing efficiency and safety in handling tasks | FDA approval for applications in food processing & clean rooms, guaranteeing compliance with stringent safety standards |

| Robust resistance to abrasion, harsh chemicals, acids, and solvents, ensuring longevity and performance even in challenging environments | Substantial reduction in conveyor system downtime, leading to increased productivity and cost savings |

| Non-marking customizable colors, maintaining cleanliness and aesthetics in diverse settings | Adjustable hardness levels, ranging from sponge-soft to iron-strong, catering to specific application requirements with precision |

| Ability to withstand extreme temperatures, both hot and cold, ensuring consistent performance in any environment | Enhanced profitability through improved efficiency, reduced maintenance costs, and extended service life |

In conclusion, the versatility and myriad benefits of polyurethane wheels make them indispensable across industries. With MPC's team of adept designers and manufacturing engineers, tailored solutions for any application are within reach, ensuring enhanced efficiency, durability, and profitability for businesses worldwide.